Benedict (Ben) Heinzl (left in the picture) and Dominik Glatzl are two creative minds from Vienna. One year ago, they embarked on the joint project „Golden Ratio“. In this interview, they share with us their fascinating maker journey and the genesis of their innovative projects. Enjoy the behind-the-scenes glimpse into how ideas transform into tangible reality.

How did you become makers, and what or who inspired you to start?

Dominik: For me, I think it all kicked off when I first picked up a hammer and lent a hand to my dad during some renovation work. It feels like it's just in my nature.

Ben: I can't pinpoint exactly when it started, but I remember taking apart VCRs at a young age. It's something I've always done. There's a floppy disk at home with the label "Benny's Inventions." Unfortunately, I can't recall what's on it since I no longer have a computer with a floppy disk drive.

Tell us a bit about your background, please.

Ben: I graduated from a technical school specializing in network technology in Vienna. I also had a course in "Mechanical Workshop" there, but that's almost negligible. After technical school, I didn't pursue anything in that direction. Instead, I ventured into theater and film, where I spent almost 10 years exclusively. Currently, I work as a full-time cameraman, shooting films and series.

The desire to build something myself was sparked through a personal project of mine – my coffee machine. However, there's only a prototype of it so far.

Dominik: I studied at BOKU (University of Natural Resources and Life Sciences). But woodworking has been my favorite subject since elementary school. It really took off when I received a bow for archery from my parents at the age of 15. I decided that a store-bought bow wouldn't suffice – I needed to make my own. So, I taught myself bow-making. Over the years, this expanded into a broader range of skills. For instance, you need a quiver, so I started working with leather, and it went on from there. It all unfolded as a hobby alongside other things.

When I lost my favorite titanium pen, I reached out to my longtime friend Ben. I had heard that he was already involved in CNC machining. So, I sent Ben a message: "Hey, I lost my pen. Can we build one?" And he said, "Well, let's give it a shot..." And that's how it all began.

So that's how the idea for your start-up Golden Ratio came about?

Dominik: Yes, we then decided that if we were going to make the effort, we should design our own pen that we could also sell. And that's how the idea for Golden Ratio came about relatively quickly, which we then established as a brand a year ago.

Golden Ratio because the basic design principle is so beautiful that the parts are all in the golden ratio to each other ...

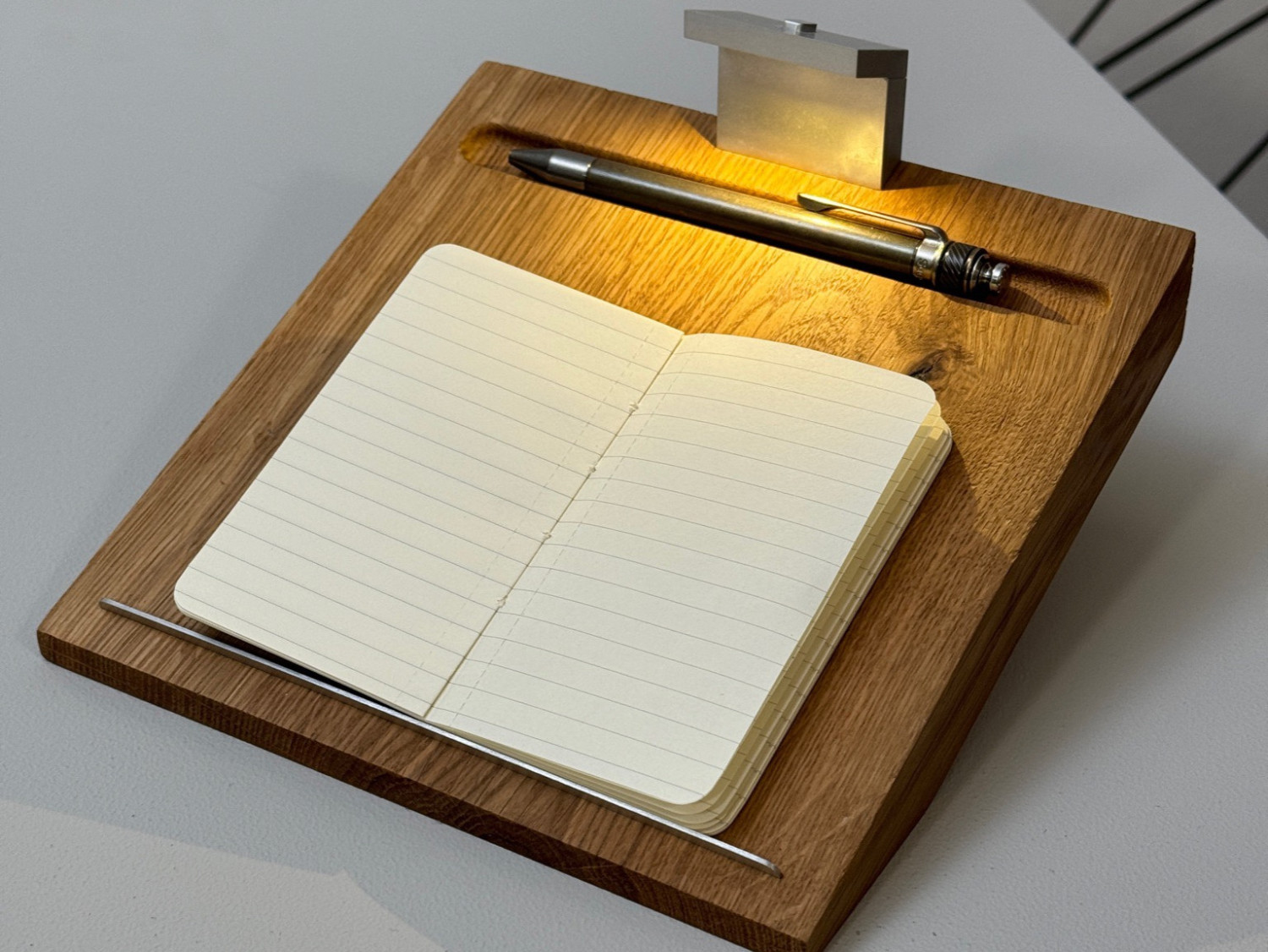

Ben: However, the biros project is a lot more complex than we thought. We now have a prototype, but we still need to work on it a little. Also, we don't yet have all the machines we need at Happylab. So we decided to focus on something else, and the idea for Epiphany, our writing desk with integrated light for the bedside table, came about relatively quickly.

What is Epiphany all about?

Ben: The idea came to me when I was falling asleep. I thought I needed something to write down when an idea came to me in the middle of the night without having to switch on the light or go out again. With our Epiphany writing desk, a small light comes on as soon as you pick up the pen. Then you write down your inspiration, put the pen down again, the light goes out and you can go back to sleep with peace of mind.

Dominik: Over the last six months, we have brought this from the idea to market launch. We already have the first items on the website and are ready to sell. The target group includes weirdos like us who have ideas all the time, or people who write dream diaries or journal and want to disconnect from technology.

You have another project that is quite unusual...

Ben: Yes, we have a second brand called Aequinox, under which we produce sports throwing knives. These knives don't have a sharp cutting edge; they're only pointed at the front.

Dominik met Alexander Bruestle during the metal laser training at Happylab. Alexander is a professional architect who came up with the perfect throwing knife. He's actively involved in the sport, has a huge collection, and has been following world champions for decades. His goal was to create the perfect throwing knife. He designed it in CAD with precise weight and balance and chose a specific material. Then he handed it over to various manufacturers and forges to be handmade. However, they couldn't achieve the precision he needed for his design. That's when he happened to come across us.

Dominik: After the training, he explained what he wanted to do. We decided to give it a try, and now the knives are on the market. We've even sent a set to the current world champion in No-Spin technique in Finland, Joel Holopainen, for testing. We are beginners in this sport ourselves, and there is no club in Vienna yet. But we could start one. So, if there's interest, please let us know!

Which tools and technologies do you use most often in your projects?

Dominik: Everything except the textile tools.

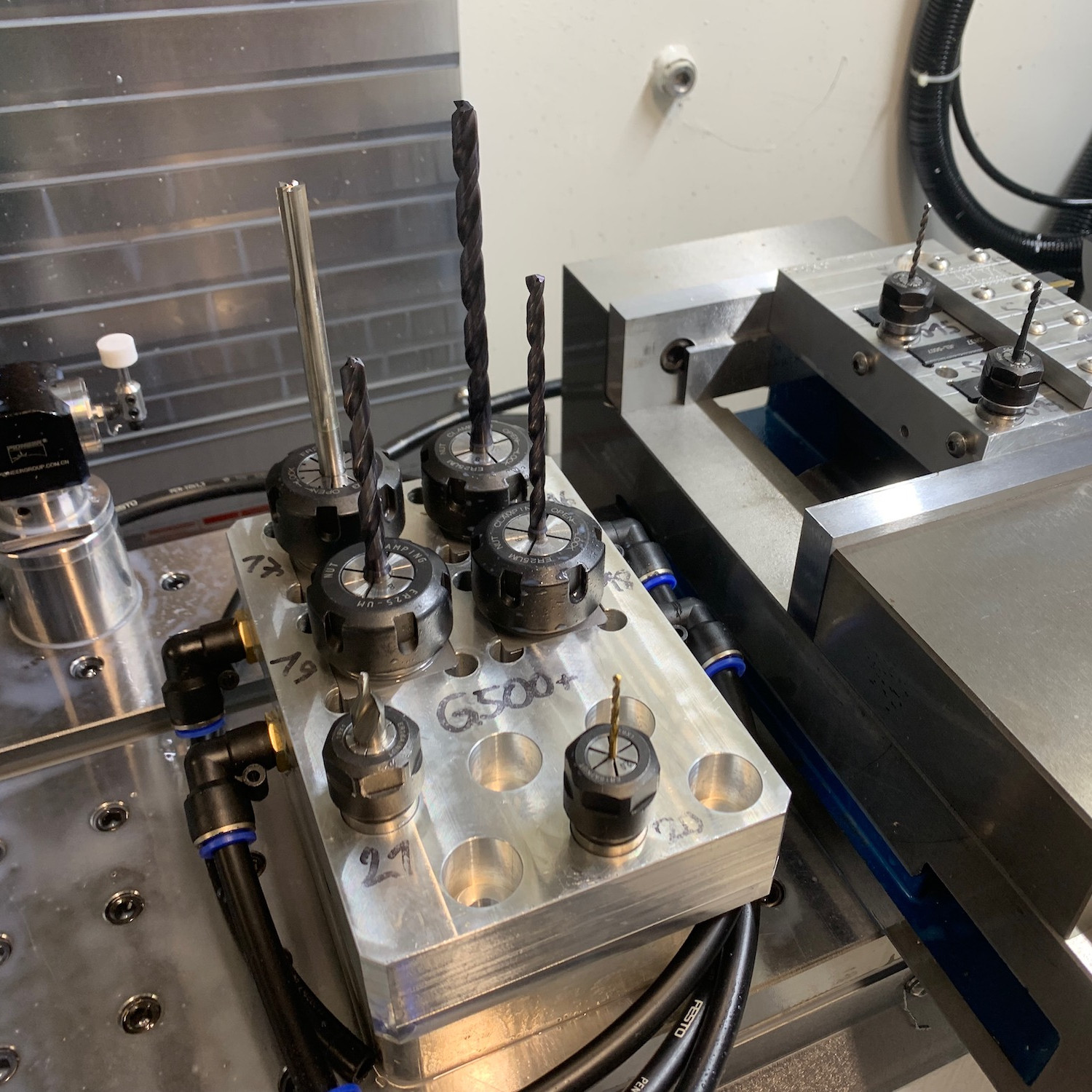

Ben: So far at least. Of course, we use the big CNC machines a lot: the SYIL, the metal laser and the AccTek. But also the thick planer and the sliding table saw.

For Aequinox, we had to build a holder for the SYIL that utilizes the entire installation space of the machine.

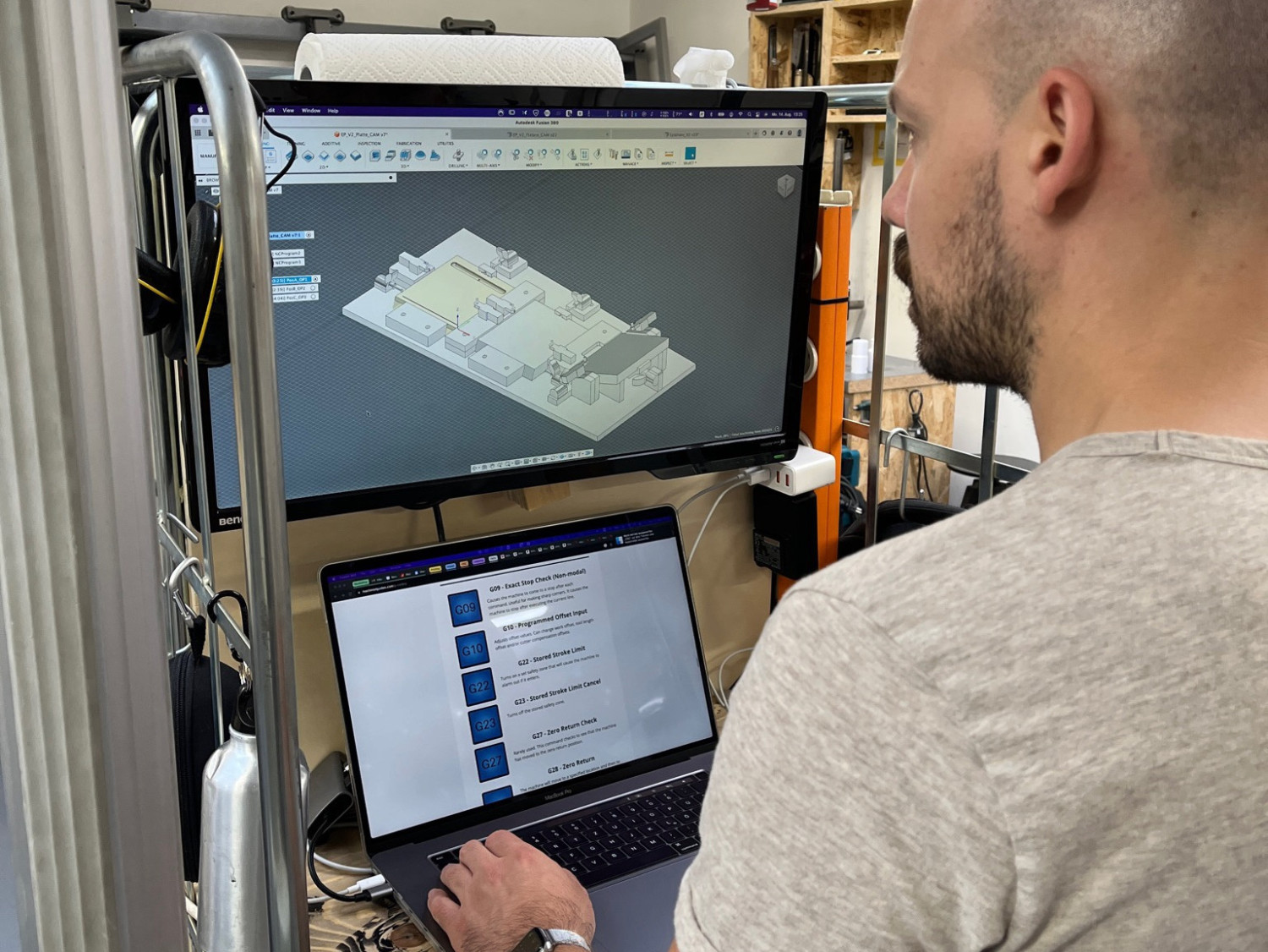

How do you develop ideas and plan your projects?

Dominik: In the beginning: whiteboard, throw it at the wall and see what sticks.

Ben: We often sat in my office or living room at home and drew ideas and tried to paint things on the wall in two dimensions that we could imagine in three dimensions.

Dominik: We define everything on the whiteboard so that it can be drawn in CAD. And then we make a 3D-printed prototype as quickly as possible to see if it works. And if that makes sense, we move on to the next step.

Ben: The development process for Epiphany, for example, was like this: we talked about the idea, drew it up, went to Happylab on the same day, printed it, cut out a piece of wood and had the version 0 prototype ready within a day. But of course it's not always that quick and easy.

Have you experienced any particular challenges or obstacles while working on projects?

Dominik: Without exaggeration: every day.

At the very beginning, for example, it was difficult to find the right milling cutters for the metal CNC milling machine. And finding out which milling cutters work for what took us a quarter of a year.

Ben: Sustainability and resource conservation are also important to us. And we also want to live that as a brand. But it's still quite an additional effort. It's particularly difficult with suppliers. It's particularly complicated with metal. Unfortunately, you don't have much choice in small quantities, like we buy, and it's hard to get certified material.

How has being a member of Happylab influenced your maker journey?

Dominik: The projects in this form wouldn't even have started if we didn't have the opportunities here.

Ben: Yes, without the equipment here we would never have been able to realise our projects. You could perhaps buy a cheap version of some of them for home use - a laser cutter, for example. But you don't have a large CNC wood router or a metal CNC router at home just like that.

Do you have any tips or advice for people who are just starting out?

Ben: The first thing that comes to mind: Don't buy the very cheapest tools, it quickly leads to frustration.

Dominik: YouTube has the answer to all questions. But when people are at Happylab, it also makes sense to simply ask them directly. Most of them are also very helpful. And if nobody is there, just read the wiki.

Is there anyone in the maker community who particularly inspires you?

Ben: John Grimsmo, a Canadian who produces extremely high quality pens and pocket knives. He also has a YouTube channel where he shares his journey. He started out with a CNC machine in his garage. Now he has a company with two halls and 15 employees. That's very informative and exciting.

Can you tell us about any future projects or plans you are currently working on or have in mind?

Ben: In addition to the biros, my coffee machine is of course still a topic. It's a mobile coffee machine that consumes so little power that you can run it on a battery, but makes coffee at the level of a portafilter machine. It only uses 250 watts compared to my machine at home, which uses 1,200 watts. And I've already taken the prototype with me everywhere, even on a shoot in Bolivia.

Dominik: We would also like to launch more products for the EDC (Every Day Carry) community. They always carry a biro, a pocket knife, a bottle opener, a small booklet etc. with them. They have collections of all sorts of different items and take something different with them every day. So things that fall into this field are bound to develop.

And what's the story behind the mat on your trolley?

Ben: It's actually there for a short nap. When it's very intense for me, I only have a short core sleep and then I have to nap in between. So when we have our 16-hour days at Happylab, I get at least half an hour's sleep on the mat in the co-working space under the table.

Thank you for sharing your experiences. We are looking forward to your future projects and wish you lots of success!